If you regularly work with metals, you probably heard about a plasma cutter. This machine can easily cut thick and hard metals as long as you use it properly.

To use a plasma cutter, connect it to the proper air source. Set the appropriate current before turning on the airflow. Doing so will turn the gas into plasma, which can cut through various metals.

However, you must also wear safety gear and understand the machine to achieve your desired results. This article will teach you the definition of a plasma cutter. Below, you will also learn how to use a plasma cutter properly.

What Is a Plasma Cutter?

A plasma cutter is a machine that uses plasma to cut different metals. It can handle hard materials, like steel, titanium, and tungsten.

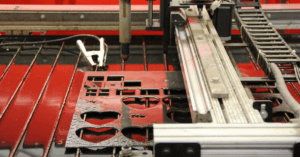

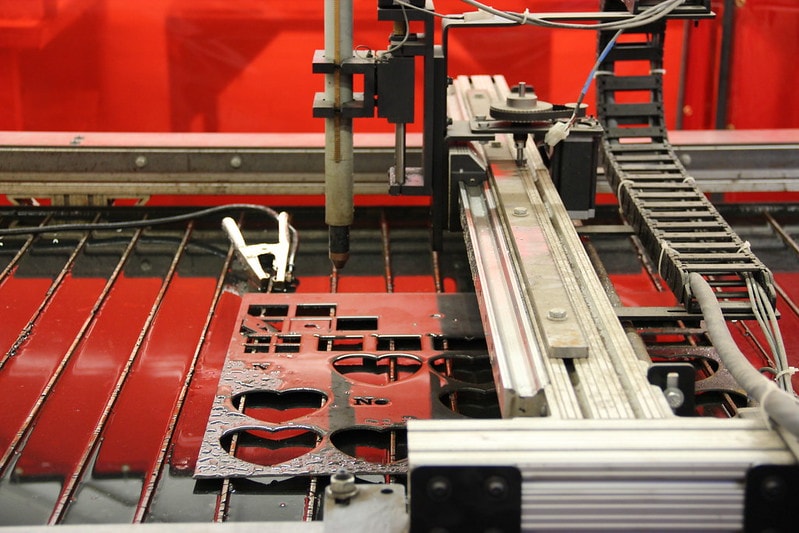

A plasma cutting system offers many applications around the workshop or any industrial setting. It can divide thick metal sheets into two. It can also puncture holes in bolts, straps, and pipes. Plus, it can cut metal into complex shapes and designs to suit artistic or creative needs.

Plasma cutters come in two categories—conventional and precision.

Conventional models use compressed air to produce plasma. They have a built-in nozzle that controls the shape of the plasma cutting arc.

Meanwhile, precision plasma cutters transform different gases into plasma. They tend to have larger designs that suit heavy-duty metalworking projects.

Choosing between the two types of plasma cutters ultimately depends on your needs.

How Does a Plasma Cutter Work?

To understand how a plasma cutter works, you must first learn the definition of plasma.

Plasma is the fourth state of matter that follows gas. It comprises most ordinary matter in the universe, such as the sun and stars. However, it rarely exists naturally on Earth’s surface because of unacceptable conditions.

That said, plasma can derive from heating compressed air and other gases. When it comes into contact with metal, it can melt the surface and leave little to no material distortion.

A plasma cutter uses plasma to cut metal. It moves pressurized gas through a constricted opening. This action creates a plasma arc that the nozzle releases to cut metal sheets.

Below are the essential components of a plasma cutting system.

Air or Gas

Plasma cutters require compressed air or natural gas, such as nitrogen and oxygen. They send a high-voltage and high-frequency electric spark to the narrow air opening. Doing so quickly increases the temperature of the gas and transforms it into plasma, the fourth state of matter.

The plasma cutting torch, which was previously shop air or gas, eventually travels toward the nozzle opening. Once it flows out and makes contact with the metal, it can instantly melt the surface.

Consumables

The consumables are the parts of the plasma cutter that gradually wear over time. They require occasional replacement to work properly.

Consumables include the following items:

- Electrode – It is an excellent electrical conductor made with a piece of copper that contains hafnium. It receives the electrical current and forms a plasma arc.

- Nozzle – It directs the plasma arc to make clean, precise cuts on the metal surface. It comes in different sizes to suit various needs. A larger nozzle can gouge the metal, whereas a smaller opening is ideal for detailed work.

- Swirl Ring – As its name suggests, this consumable swirls the gas surrounding the plasma arc. It can direct and cool the plasma. Hence, it can prevent the nozzle from degrading quickly.

- Retaining Cap – It holds all the consumable parts together. It eventually degrades because it also makes contact with the plasma cutting arc.

- Shield Cap – It acts as a protective shield around the plasma torch tip and components. It minimizes wear to other parts of the cutter.

What Is Plasma Cutter Used For?

A plasma cutter offers several applications around the workshop.

First, it is a popular tool for metal fabrication. It can handle both small and large construction projects. It is also ideal for metal scrapping and automotive repair.

A plasma cutter is also a great tool for general metal plate cutting. It can slice through aluminum, brass, copper, and titanium, among other materials.

A plasma cutter can even produce bevel cuts, drill holes, and perform other precise work. It can ultimately suit artists and designers.

How To Use a Plasma Cutter? 9 Easy Steps to Follow

A plasma cutter can be tricky to use, especially for beginners. Below are some tips to follow to ensure proper usage of the machine.

Purchase the Right Plasma Cutter

The first step is to find the right plasma cutter that suits your needs. It will largely determine the success rate of your project.

Below are some factors to consider.

Output Power

The output of the plasma cutter depends on the type and thickness of metal to be cut.

The thickness is expressed in two standards. A rated cut describes the depth you can cut at a rate of 15 inches per minute (IPM). Meanwhile, the sever cut determines the maximum thickness the machine can perform.

Input Power

Plasma cutters come in a wide range of input power options. Most models have a single power source, whereas others can switch from different voltages.

Choose the single input model if you work in the same location. But if you need portability, invest in a plasma cutter that can switch from 120-volt to 240-volt power.

Cutting Speed

The cutting speed of a plasma cutter is expressed in inches per minute (IPM). It determines the time it would take to cut through a metal sheet.

Most plasma cutters operate with cutting speeds of up to 200 IPM on steel. Make sure to buy a model with more or less the same efficiency.

Duty Cycle

The duty cycle measures how long a plasma cutter can operate without overheating. It is usually measured against a 10-minute cycle.

For example, if the machine has a 70% duty cycle, it can run continuously for seven out of 10 minutes. Then, it needs to cool down for the remaining three minutes.

Invest in a plasma cutting machine with a larger duty cycle when making long cuts.

Size and Weight

Choose a handheld plasma cutter if you need portability to perform detailed work. But those dealing with large-scale projects must invest in large models like the CNC plasma cutter.

Use Safety Gear

After selecting the proper machine, you must consider your safety. Know that using a plasma cutter is very dangerous when you are not careful.

Invest in a pair of welding gloves, a welding jacket, and other flame-resistant clothing. You are dealing with extremely hot temperatures here, so ensure you are wearing proper clothes.

You must also use safety goggles to protect your eyes from sparks. Or better yet, get a protective welding helmet.

And if you have sensitive hearing, you can wear earplugs or ear muffs.

Follow all these safety procedures to keep yourself from harm during plasma cutting.

Read the Product Manual

Wearing safety gear does not mean you are 100% safe from accidents while operating the plasma cutter.

You must also be familiar with the machine to ensure safe and correct operation. Thoroughly read the product manual to learn about each component of the plasma cutter.

You might also want to check the manufacturer’s website for specific tips on handling the machine.

Doing your due diligence can ultimately promote the safe use of the plasma cutter.

Prepare the Plasma Cutter

By now, you have probably familiarized yourself with the plasma cutter. The next step is to prepare the machine and material for the task.

Place the metal on a table and secure it using a ground clamp. Attach it as close to the cutting area as possible.

Avoid clamping rusted metal because it can affect the flow of electricity. Make sure to remove any rust and paint before you secure it to the workbench.

You might also want to check the cables of the machine. Untangle the knots or tighten loose connections because they can prevent proper electrical flow. Then, plug in the plasma cutter.

Connect the Air Supply

Connect the plasma cutter to the external air compressor or gas source.

Consult the owner’s manual for specific installation instructions. But in general, you can attach the fittings by pulling the female connection and inserting the male one.

Before turning on the power, check if the machine has the correct airflow and air pressure. Again, check the manual for air requirements.

Note that you must use dry air to maximize the plasma cutting capacity. You might want to install an air filter on the plasma cutter if it lacks one. Regularly clean and replace the filter to ensure proper working condition.

Set the Current

To set the proper current in amperage, use the highest setting first. Turn on the plasma cutting machine and make a few practice cuts on the material.

You can change the amperage later based on your cutting or travel speed.

Note that a too-high amperage results in overheating and accumulated debris on the material. Use adequate electric current to prevent these problems.

Cut the Metal

After adjusting the current, it is time to cut the metal.

Lift the trigger safety lock before pressing the trigger itself. Doing so will produce the plasma arc that can cut metal.

Gently guide the nozzle end of the plasma cutter close to the metal. Avoid direct contact with the surface. Instead, let the plasma cutter hover at least several centimeters away from the material.

Check if sparks are flying from the bottom of the metal. If not, adjust the power and speed of your plasma cutter to penetrate the thickness of the material.

Slowly move the plasma torch across the metal surface for even results.

Use the Appropriate Cutting Speed

The right travel speed results in clean cuts. It can also minimize the amount of debris after cutting.

We recommend adjusting the travel speed when working on thick metals. Check the plasma torch to see if the arc flows out at a 20-degree angle opposite the traveling direction. If it is moving straight down, you are too slow. But if it sprays backward, you are too fast.

Use a slower cutting speed when handling thinner materials. Doing so ensures a narrow kerf and minimal distortion on the metal.

Turn Off the Plasma Cutter and Air

When you are finished cutting the metal, turn off the plasma cutter. Detach the clamp that keeps the metal secure.

Then, disconnect the plasma cutter from the air source.

Remember to wind up all the hoses and external connections. These include the plasma gun line, air line, and ground cable.

Frequently Asked Questions

Do you need an air compressor for a plasma cutter?

Yes, you must connect an air compressor to the plasma cutter to penetrate metals.

Note that the machine creates plasma from hot gas. Without an air compressor, the machine has no gas to convert into plasma.

Fortunately, you will find that most plasma cutters have a built-in air compressor. If your machine does not contain one, you can purchase a separate compressor. Choose a model with an airflow of around 4-8 standard cubic feet per minute (SCFM) at 90-120 pounds per square inch (PSI). This unit is powerful enough to cut through thick steel and metals.

Does a plasma cutter need water?

It is essential to have a waterbed or water pan when working with a CNC plasma cutting table. CNC stands for computerized numerical control. It uses pre-programmed codes to operate the plasma cutter. However, it generates a lot of dust and fumes during the cutting process.

Placing a water pan underneath the metal being cut minimizes the debris. The liquid can also prevent metal distortion and warpage.

How thick of metal will a plasma cutter cut?

In general, a handheld plasma cutter can penetrate mild steel and metals up to 1.5 inches thick. Meanwhile, a heavy-duty industrial plasma cutter can cut through metals with 6 inches of depth.

If you intend to cut metals thicker than 6 inches, consider a waterjet cutting or oxy-fuel cutting system.

Conclusion

A plasma cutter is a powerful machine that can cut through different metals.

To use a plasma cutter, you must understand how it works. Doing so will make it easier to set the proper airflow and electric current. Refer to our other usage tips above for a successful cutting job.

Do you have more questions about plasma cutters? Feel free to send your queries to our contact page!