Nothing is more frustrating than making precise cuts on metal workpieces. If you have ever tried to create complex shapes with a saw, welcome to the club. Consider using a metal lathe to make the job easier.

To use a metal lathe successfully, you must first learn the basics. These include the components, safety materials, and tools required. After that, you can clamp the metal workpiece and turn on the metal lathe to start shaping the material.

Besides shaping metal, you can also use a metal lathe for drilling. This article will guide you on how to use a metal lathe, whether for cutting or drilling. But first, we will cover the definition of this tool.

What Is a Metal Lathe?

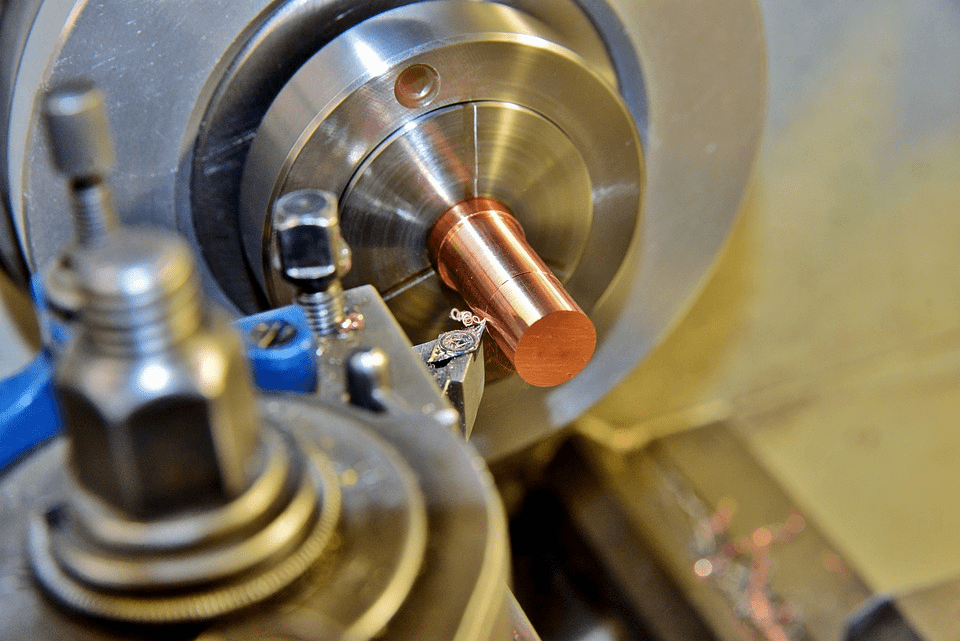

A metal lathe is a type of lathe specifically designed for metal workpieces. It has a rotating spindle and a stationary cutting tool. The former holds the metal and spins it against the cutter, while the latter removes unwanted material.

A metal lathe can cut metal into specific shapes and sizes. It can also handle other industrial tasks. These include cutting, drilling, sanding, threading, and turning metal, among others.

Overall, a metal lathe is a versatile tool used for a wide range of operations. It is common in automotive, engineering, machinery, and tools.

What Are the Different Types of Metal Lathes?

Metal lathes come in different types, depending on their design and function. Below are the main kinds of metal lathes.

Engine Lathe

Also known as a center lathe, it is the most common type of lathe. It uses steam engines as a power source, which delivers continuous rotation.

Engine lathes can handle various tasks, such as boring, drilling, facing, and threading metal.

Turret Lathe

This type of metal lathe has a built-in rotating turret that can hold several cutting tools simultaneously. The tool turret can quickly create duplicate or identical metal workpieces.

CNC Lathe

CNC stands for computer numerical control. This type of lathe uses computer software to automate the machining process. It lets you change spindle speeds and cutting tools easily.

Tool Room Lathe

A tool room is a heavy-duty metal lathe. Like the engine lathe, it uses a steam-powered engine. Tool room lathes can also produce precise cuts on metal workpieces.

Bench Lathe

A benchtop metal lathe has a compact size. It can suit DIY projects, hobbies, and other small-scale machining tasks.

What Are the Things You Need to Know Before Using a Metal Lathe?

You must first understand the basics of a machining tool if you want to learn how to use a metal lathe. Below, we will teach you the essentials for safe and efficient lathe use.

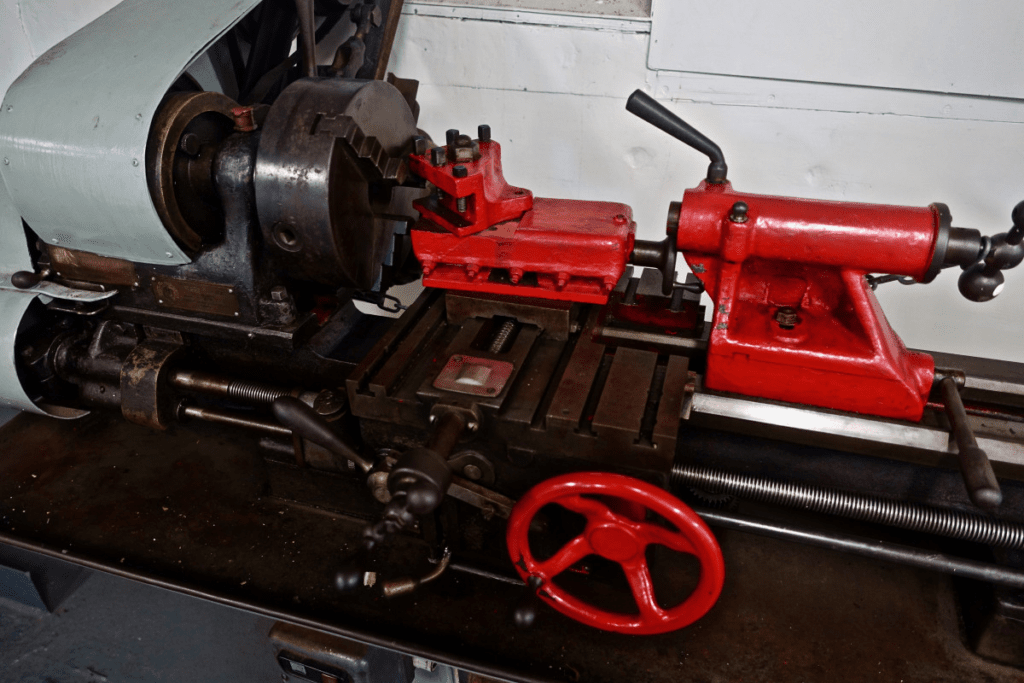

Machine Components

The metal lathe comprises different parts. The primary components are the bed, headstock, tailstock, and cutting tool post. However, we will also cover other lesser-known parts essential to the machining process.

- Bed – This horizontal base supports the other parts of the metal lathe. Its length usually determines the maximum size of the metal that can be cut on the lathe. A longer lathe bed can handle large metals and several cutting tools.

- Headstock – Situated at the left part of the bed, it holds various drive components. These include the motor, gearbox, and belt drive.

- Tailstock – It is located on the opposite side of the headstock. It has built-in clamps that hold and support long metal workpieces.

- Carriage – It is located on the bed and moves along the length of the metal lathe. It features a hand wheel to control the carriage movement.

- Cross Slide – It moves perpendicular to the bed, which allows you to change the position of the cylindrical cutters. It determines the depth of the cut during the machining process.

- Compound Slide – It is mounted on the cross slide. It lets you adjust the cutting tool at an angle with the workpiece. Hence, it can produce beveled and tapered cuts.

- Toolpost – Also known as the tool rest, it houses the cutting tool bit essential for the lathe operation. It usually sits on the cross slide, which lets you adjust the tool positioning. It can also hold numerous cutting bits simultaneously, depending on the design.

- Spindle – This rotary component drives the chuck and metal workpiece. It usually consists of a single spindle, but multi-spindle models are also available for improved productivity.

- Chuck – This clamp holds the metal workpiece while the spindle rotates it against the cutting tool bit. It usually comes in 3-jaw or 4-jaw configurations. The former has an automatic adjustment, while the latter offers manual control.

- Apron – It is located on the lathe carriage. It lets you set an automatic feed during the machining operation.

- Feed Rod – This long shaft transfers power from the headstock to the apron gears.

- Lead Screw – It is another long driveshaft with distinct threads on it. It can help you achieve your desired shape or size of metal.

Safety Tips

Operating a metal lathe could be dangerous and lead to severe injuries due to the sharp cutters. You must take the necessary precautions to ensure your safety.

First, wear appropriate clothing and safety gear. Dress in snug-fitting garments and avoid loose clothes. You must also remove dangling jewelry, rings, and watches to prevent them from catching on the rotating workpiece.

As for the safety gear, invest in goggles or a face shield to protect your eyes from debris. You can also wear a mask to prevent inhaling the dust generated by the metal lathe machine.

It is also best to understand how the lathe machine works to keep you safe. Learn every part of the metal lathes and their functions. Then, know the emergency stop, which you can push when the operation becomes dangerous.

Another safety tip is to use pliers or a brush when removing metal chips or shavings. Avoid using your bare hands to clean debris because you might accidentally cut yourself.

Moreover, you must always keep the working area clean and organized to lower the risk of accidents. And if you plan on storing tools on the toolpost, keep them as short as possible.

Finally, turn off the power and unplug the metal lathe machine when not in use. You must also properly store the chuck keys and other cutting tools. Keep them out of children’s reach and sight.

Cutting Tools and Equipment

A metal lathe is a versatile machine that accepts various tools and equipment. Each one can help you achieve specific metalworking tasks.

- Turning Tool – It comes in two types—rough and finish turning tool. The former can remove a lot of metal, while the latter can only take off a small amount of metal.

- Chamfering Tool – It creates an angle or beveled cut on the metal workpiece. It smoothens the sharp edges of the material.

- Facing Tool – This lathe machining tool removes metal from the end of a workpiece to achieve a flat surface.

- Thread Cutting Tool – As its name suggests, it cuts through metal, making it ideal for producing screw threads.

- Grooving Tool – It produces square, round, or V-shape cuts, depending on the shape of the tool.

- Boring Tool – It uses a single-point cutting tool to expand the existing cut on the metal workpiece.

- Counterboring Tool – This specialized drill bit can enlarge a pre-drilled bore. It is commonly used when the machine cannot allow solid drilling of a specific size.

- Forming Tool – It can bend and shape sheet metal to create unique forms. These can vary from simple patterns, like louvers, to complex designs, such as ribs.

- Undercutting Tool – This metal lathe tool suits internal threading and groove cutting.

The tools for the metal lathe can also be divided based on the method of applying feed.

- Right-hand Tool – It removes metal moving from right to left. It is the most common metal turning motion, which cuts towards the lathe chuck.

- Left-hand Tool – It is the opposite of the right-hand tool. It moves the metal from left to right. And the cutting edge is on the right.

- Round Nose – This metal-turning lathe tool has no back or side rake. Hence, it allows left-to-right or right-to-left movement on the lathe bed.

How to Use A Metal Lathe?

Now that you understand the basics of a metal lathe, you can start using it to shape metal. Below is a step-by-step guide on how to use a metal lathe.

First, you must set up the lathe and the cutting tool based on your project. For instance, get a bench lathe if you are working on small-scale projects. Then, mount this machining tool on a sturdy table or pedestal.

As for the cutting tool bit, ensure it is sharp and clean before securing it to the machine. You must also keep the cutting bit in the center to shape the metal effectively.

After preparing the metal lathe, place the metal into the headstock. Attach it to the chuck to secure its position. If your model has one, put the chuck guard on to protect yourself from the sharp edge.

Turn on the metal lathe. Start at the slowest rotation per minute (RPM) rating, which determines the spindle speed.

Then, slowly move the tool holder or post near the rotating workpiece. Give the material a light pass to familiarize yourself with the feeling of metal grinding.

Once you are used to the movement, you can adjust the RPM or spindle speed and slide the carriage based on your needs. You can also angle the metal workpiece to achieve specific cuts.

Consider switching the machine on and off to make several passes on the metal. Keep the chuck rotating until you have removed all the unwanted material.

Finally, turn off the metal lathe if you have achieved your desired result. Unplug it to prevent accidents.

How to Drill With A Metal Lathe?

You can also use a metal lathe to drill into metal. The steps required are different from shaping the material.

So, below are the steps for drilling metal with a machining tool.

First, you must drill at the center of the metal workpiece. Use the appropriate drill bit for the task. Then, set the spindle speed at high to penetrate the surface of the metal. No need to drill a deep hole—it simply must be in the center.

Once the center drilling is done, you can move on to pilot drilling. Doing so makes clearance for the chisel tip when using a bigger drilling bit. If you skip this step, you cannot cut with a too-large tip. So ensure to remove enough material to fit the larger tip.

After that, use a larger drill to create a big hole inside the metal workpiece. You can go as deep as the material permits you.

Finally, drill the metal with a reamer. It is a finishing tool that provides a smooth finish and accurate hole measurement.

How to Take Care of a Metal Lathe?

Metal lathes are heavy-duty machine tools that can withstand daily use. However, they require regular maintenance to ensure optimal working conditions.

Ensure to clean the lathe after each use. Wipe off debris, shavings, or spilled coolant product with a dry cloth brush.

Then, apply lubricant to the moving parts of the metal lathe. Doing so can prevent friction as well as daily wear and tear.

Consider checking the belts and gears. If you notice damaged or worn-out components, replace them as soon as possible.

You must also check if the bed, headstock, tailstock, and tool rest are aligned correctly. Fix any misalignment because it can damage the machine.

Finally, store the metal lathe when not in use. Choose a clean and well-ventilated area. Then, cover the machine with a cloth to protect it from debris.

What Can You Make With a Metal Lathe?

A metal lathe is a versatile machining tool used in various sectors. Below are some of the items you can make with a metal lathe.

- Bowls

- Carvings

- Doors

- Jewelry boxes

- Mallets or hammers

- Pens

- Rings

- Spindles

This tool is also widely used in the aerospace, automotive, construction, and shipbuilding industries.

Conclusion

A metal lathe is a popular machining tool for shaping metals with precision. However, it is challenging to use, especially for beginners and hobbyists.

You must first learn the basics before using a metal lathe. Understand the components and tools required for your project. Then, take the necessary precautions. After these steps, you can turn on the metal lathe to shape the material.

Do you have other questions about metal lathe usage? Visit our contact page to send your queries!