As a DIY home builder, I know it can be intimidating to cut metal with a Dremel for the first time. It might seem like this compact tool is incapable of metalwork, but I assure you that it does the job effectively. So, I put together this guide to show you how to cut metal with a Dremel.

Prepare the working area and choose the right Dremel tool attachment if you want to cut through a metal sheet. Ideally, you want to use small cutting discs for precise grooves.

Note that cutting metal is different from carving wood. For one, you will feel like the cutting tool is about to break any minute. So it is essential to know the proper handling of the Dremel Multi-Tool. Below, I will teach you step-by-step how to cut sheet metal efficiently and safely.

How to Cut Sheet Metal With A Dremel? 9 Easy Steps to Follow

Whether you need to divide a sheet metal into two or make detailed cuts, this step-by-step guide can help you cut metal properly.

Wear Appropriate Safety Gear

Safety gear is a must-have when cutting sheet metal with a Dremel. Although rare, metal parts can fly at your face when grinding discs break accidentally. So before you start cutting, ensure you have protective equipment.

Wear safety glasses or safety visors. Doing so can help keep your eyes safe from sparks and small metal pieces.

I also recommend you wear gloves and put on hearing protectors. These items can protect your hands and ears from hot metal and loud grinding noises respectively.

And while you can wear everyday clothes when cutting metal, it is best to dress in a covering attire. These include a long-sleeved shirt or sweater and ankle-cut pants. They can prevent flying sparks from burning your skin.

Finally, slip on steel-toe shoes when working with Dremel and metal. This type of footwear can protect you from heavy materials if they accidentally fall on the floor.

Prepare the Working Area

After taking the needed precautions, arrange the workspace. You are better off cutting metal outdoors than indoors, but you can still set up the working area inside your home. Just ensure the room has great ventilation.

Choose a durable surface where you can cut the sheet metal. Then, clamp the panel down to a metal vise or workhorse. The last thing you want is the sheet metal to move around once you start cutting. Having a wobbly metal piece can lead to uneven results or, worse, accidents.

Select the Right Dremel Tool Attachment

You also need to prepare the Dremel Rotary Tool itself for metalwork.

You can choose from different Dremel cutting attachments. Each one has its pros and cons. So consider your needs and desired results before picking the right Dremel cutting tool.

For example, the Lock cut-off discs with an EZ-lock system are more durable and convenient for cutting a metal sheet. The only downside is that these Dremel bits are quite slow. In contrast, thin-cut wheels and mandrel bits offer faster cuts due to their lighter build and smaller size. However, they can break when penetrating thick pieces of metal sheets., like hardened steel.

Attach the Dremel Tool Bit

Once you have picked the Dremel tool accessory, it is time to attach it to the Dremel.

Remove the existing bit connected to the Dremel Rotary Tool.

Next, loosen the screw at the end of your chosen cutting disc or mandrel.

Then, insert the tool bit into the Dremel device.

Finally, use a screwdriver or wrench to tighten the accessory. Make sure the Dremel cutting wheel or mandrel is secure before moving to the next step.

Mark the Cut

Do you want to achieve a straight cut or create complex carving designs on metal? Then, you will need to mark the desired pattern before making the cut.

Stick low-adhesive tape along the cut line. Doing so can prevent scratches on other metal surfaces. Then, draw cutting lines or designs on the tape surface with a pencil.

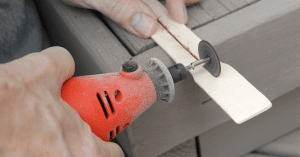

Turn On The Dremel

After labeling the cut mark, you are now ready to cut.

Hold the Dremel tool tightly with both hands for maximum stability. Then, set the RPM between 25.000 and 35.000.

Ensure the cutting disc is perpendicular to the metal sheet before turning on the Dremel Multi-Tool.

Cut the Metal Sheet

Cutting sheet metal will feel weird at first, especially if you are used to working with wood. It might seem like the cutting wheel can break at any moment. You will also notice that working with metal pieces is slower than grinding wood.

Now, you may be tempted to push the cutting disc through the metal to speed up the process. However, avoid doing this because it can damage the Dremel bit or mandrel. Leave the device to do the work instead.

Keep a steady hand and apply just a little bit of pressure. You can determine the right amount of force via trial and error. It can vary depending on the metal type, Dremel attachment, and cutting depth.

Reduce pressure when the cut-off wheel gets closer to the end. Doing so can prevent the Dremel from jerking because of a lack of resistance.

Turn Off The Dremel

After cutting sheet metal, turn off the Dremel Multi-Tool. Unplug the versatile tool from the socket to prevent others from switching it on accidentally.

Avoid Touching the Dremel After Use

Now that you are finished with the Dremel device, you might be tempted to store it away for safekeeping.

However, do not touch the Dremel after immediate use. The reason is the device can get very hot due to friction. Allow the metal and grinding bit to become cool before removing the attachment and storing it.

Frequently Asked Questions

What is the best Dremel bit to use to cut metal?

The best Dremel tool accessory for cutting metal will depend on your needs and desired results. However, we found the cut-off wheels ideal for cutting, grooving, and trimming most types of metal. They can also penetrate wood and plastic. Plus, these cutting wheel bits are available in various sizes to suit different projects.

How deep can you cut a metal sheet with a Dremel?

The Dremel Multi-Tool allows you to cut a metal sheet up to 1.1 inches (2.8 cm) thick. If you need to pierce through thicker metal, use other power tools like an angle grinder or die grinder.

The Dremel cannot go any deeper because the largest cutting wheels have a radius of ¾ inches or about 1.9 cm. However, the actual sharp edge limits you to a cutting radius of around 0.6 inches (1.5 cm). You will need to grind a 1.1-inch metal sheet from both sides to achieve your desired results.

Can a Dremel cut through screws?

Yes, a Dremel Multi-Tool can cut through screws and other compact metal objects. Make sure to choose the proper rotary tool bit for this purpose. Look for small cutting wheels to pierce screws or stripped bolts.

Conclusion

Metal cutting can seem intimidating at first. However, the truth is that the process is straightforward.

Follow our tips on how to cut sheet metal with a Dremel above. Once you prepare accordingly (especially in terms of your safety) and choose the right Dremel tool attachment, you can make straight or decorative cuts on metal.

Do you need further help in cutting metal pieces? Drop a message on our contact page, and we will get back to you soon!