If you want to cut hard metals, you know it is difficult and slow using a mechanical saw. Consider a plasma cutter to speed up the production process.

A plasma cutter works by heating compressed air or other gases to create plasma. The cutter uses this electrically conductive ionized gas to slice through various metals with ease. It ensures quick and clean cuts on the surface.

A plasma-cutting system is suitable for different tasks, which we will explore below. This article also covers the benefits and downsides of this industrial tool. But first, we will teach you the definition of plasma and how it works.

What Is Plasma?

Before diving into how a plasma cutter works, we first want to cover what plasma is.

Plasma is the fourth state of matter. Now, this fact might surprise you. After all, most of us only think that matter has three states: solid, liquid, and gas.

Plasma makes up the majority of ordinary matter in the universe, including the stars and the sun. However, it is quite rare on Earth due to the conditions required to keep the gas in the plasma state.

Artificial plasma comes from burning gas at extremely high temperatures. These cause an electron or two to tear free from an atom. The gas will become ionized and electrically conductive to suit various needs.

Plasma is common in televisions, neon signs, fluorescent lamps, and of course, plasma cutters.

What Is a Plasma Cutter?

A plasma cutter is a device that can cut through conductive metals. These include aluminum, brass, copper, steel, and titanium, among other materials.

A plasma cutting system can divide metal sheets into two. It can also create holes in metal plates, bolts, straps, and pipes. It suits various industrial tasks. However, it is also versatile enough to handle creative projects.

A plasma cutter usually comes in a handheld form, also known as a plasma torch or gun. It can quickly slice through thick metals, such as stainless steel. At the same time, it is easy to carry and handle. It allows you to carve complex shapes and designs on the material, which is ideal for artists and hobbyists.

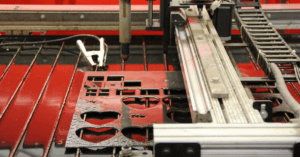

Plasma cutters are also available in large models to handle demanding and heavy-duty tasks. The most common type is called a CNC plasma cutting table. It features computer numerical control (CNC) plasma to direct the plasma gas flow. It ultimately provides quick, accurate cuts to suit large metal fabrication projects.

How Does a Plasma Cutter Work?

Plasma cutters come in different types, and not all systems function the same way.

But in general, a plasma cutter involves a thermal cutting process. It works by using hot plasma to melt and slice the metal instead of cutting it mechanically.

A plasma cutter creates plasma by burning compressed air or other gases, such as nitrogen and oxygen. The intense heat transforms the gas into the fourth state of matter called the plasma.

As more gas becomes plasma, the pressure inside the cutter builds up. The equipment uses electricity to ionize the plasma gas.

Once plasma becomes electrically conductive, the cutter eventually releases all the tension through a small nozzle. It causes the plasma jet to flow out and become an electrical arc. This plasma arc quickly cut through conductive metals.

What Are the Components of a Plasma Cutter?

Most plasma cutters include three basic parts to slice through sheet metals.

- Power Supply – It transforms the AC voltage into constant DC voltage, ranging from 200 to 400 VDC (volts direct current). The direct current maintains the plasma arc or heat throughout the cutting process. It also regulates the required electrical output depending on the metal type and thickness.

- Arc Starting Console – It uses high voltage to create a high-frequency spark. The ionization process begins, which turns plasma to become electrically conductive. It eventually forms a plasma electric arc for cutting.

- Plasma Torch – It ensures the proper alignment and cooling of the consumable parts. These include the electrode, nozzle, and swirl ring.

Some plasma cutters have computer numerical control or CNC. These models let you direct the power and direction of the electric arc via a computer.

What Are the Types of Plasma Cutters?

Plasma cutting systems have two primary categories.

- Conventional Plasma Cutter – It encompasses all handheld plasma cutting systems. It uses compressed or shop air to create hot plasma gas that can cut metal. The nozzle determines the shape of the plasma arc.

- Precision Plasma Cutter – It comprises large cutters suitable for demanding tasks. The most popular example is the CNC plasma cutting table. It uses different gases, such as nitrogen, oxygen, and argon, to produce plasma. It also features a more complex torch design for a different plasma arc shape.

Where Can You Use a Plasma Cutter?

A plasma cutter has many uses in and outside the workshop.

The most common application of a plasma torch cutter is metal fabrication. It is ideal for on-site construction projects, whether small or large. It is also popular among salvage yards with metal scrapping operations. It can even be used in automotive repair and restoration.

Plasma gas cutters can also handle general sheet metal cutting. It offers fast, accurate slicing performance that is ideal for large metals. Plus, it is relatively more affordable than other cutting methods.

Finally, a plasma cutter suits the needs of artists and designers. It can produce bevel cuts, bore precise holes, and cut in any way to create unique art pieces. These tasks are impossible to do with standard metal-working tools.

What Are the Advantages of a Plasma Cutter?

Plasma cutters offer several key benefits.

First, they can cut through electrically-conductive metals. These include aluminum, copper, steel, and stainless steel, among others.

The plasma cutting process also delivers precision and speed. It can divide metal sheets without material distortion.

Moreover, these plasma cutting machines are versatile. They are suitable for beveling, marking, piercing, and cutting shapes. They can even create unique shapes, like domes or tubes.

Plus, most plasma cutting involves compressed air, nitrogen, and oxygen. There is no need to use flammable and volatile gases, which could be dangerous.

Finally, using a plasma cutter is cheaper than other metal-cutting tools.

What Are the Disadvantages of a Plasma Cutter?

While plasma cutters have several advantages, they still have their share of downsides.

First, plasma cutters can only cut thin metal sheets and plates. They struggle when slicing through thicker metal layers.

Plasma cutters can also be more dangerous than conventional metal working tools. They produce heat that causes severe burns if you are not careful. Wearing safety gear is essential when using these tools.

Plasma cutting systems are also noisy. Use ear plugs or ear muffs to protect your hearing.

Conclusion

Cutting metal with a saw requires physical effort and too much time. Use a plasma cutter to make the task more efficient.

A plasma cutting system works by heating gas (usually compressed air or nitrogen) and transforming it into plasma. The hot plasma melts and cuts the metal with minimal distortion.

Do you have other questions about plasma cutters? Feel free to visit our contact page to send your queries.