Table saws are powerful woodworking tools used to cut large pieces of wood to size and are an investment for woodworkers.

These come in many makes, models and price ranges which can make it hard to tell which one to buy especially if you’re on a budget. In this article, we’ll be going over the best table saws under $1000 that are available online and things to know before you buy. Here’s a list of the models we recommend in case you’re in a hurry.

Quick Summary of Best Table Saw Under 1000

| IMAGE | PRODUCT | |

|---|---|---|

Editor's Choice  |

| View On Amazon →Read Our Review |

Runner-up  |

| View On Amazon →Read Our Review |

|

| View On Amazon →Read Our Review |

|

| View On Amazon →Read Our Review |

|

| View On Amazon →Read Our Review |

Best Table Saw Under 1000 / Our Top Picks

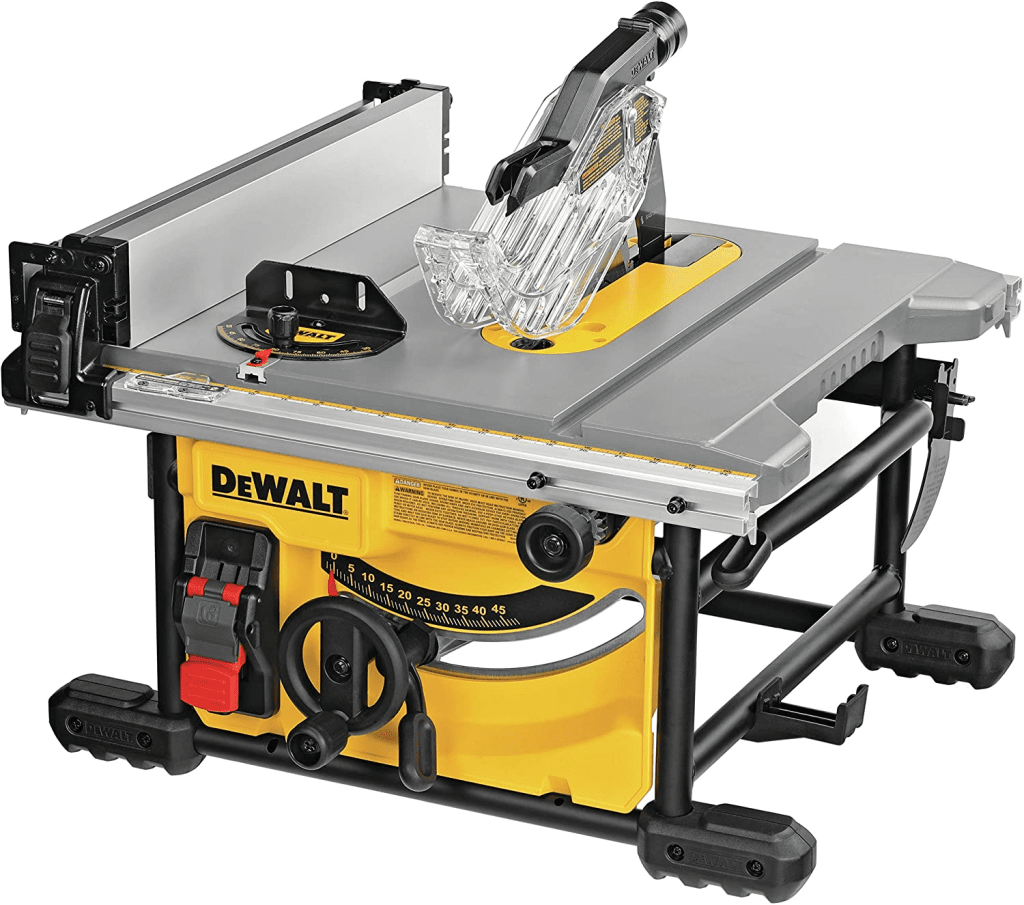

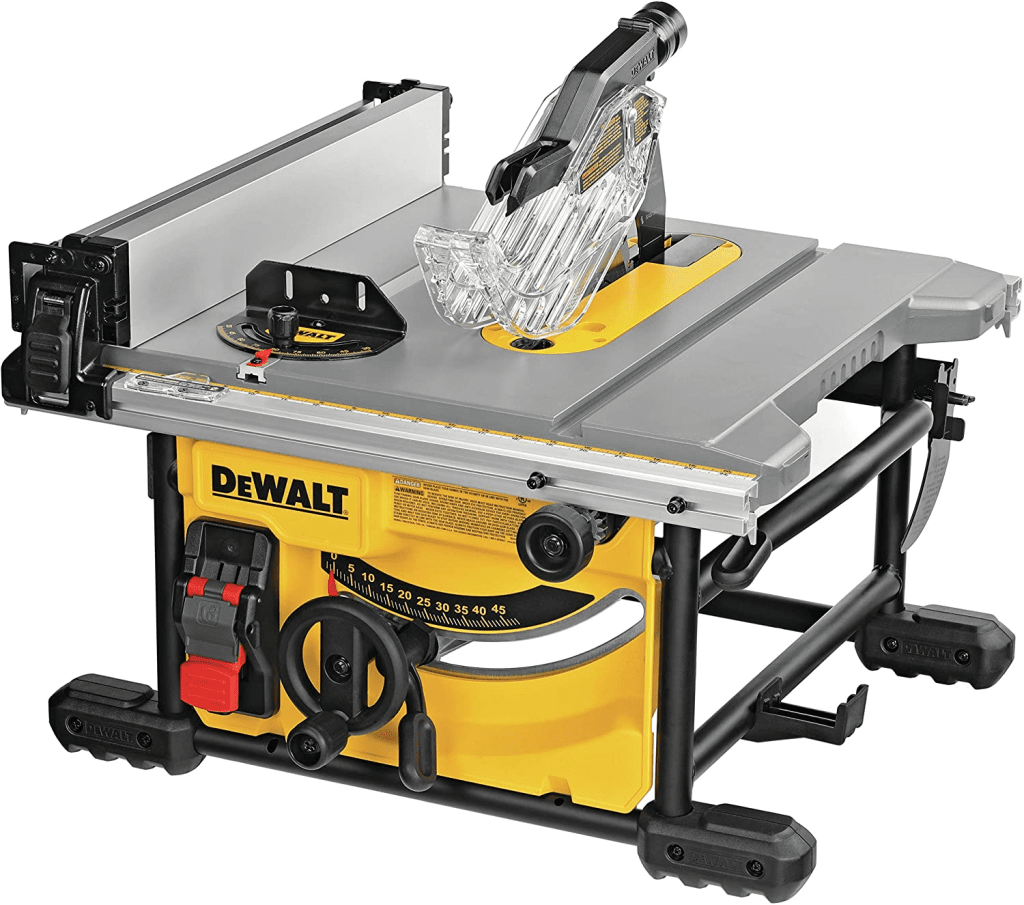

DEWALT DWE7485

Features

- Comes with one 8½ inch carbide tip blade

- Push stick, riving knife and pawl included

- Blade guard with dust collection port

- Rack and pinion telescoping fence rails

- Steel roll cage

- Large cast aluminum table

- Built in accessory slots

Specifications

- 8.25 inch blade

- 24.5 inch rip capacity

- 54 lbs

- 15 amp motor, 5800 RPM no load speed

Overview:

This quality table saw from Dewalt provides users with a 15 amp, 5800 RPM motor allowing for lots of consistent and accurate cuts.

This benchtop table saw features a rack and pinion system for accurate adjustments to the fence, a miter gauge and a number of safety features. A folding stand and rolling stand are available for this model but are sold separately.

This makes it a great choice for the beginner woodworker looking for a starter table saw that provides power in a small package.

Check out the DEWALT DWE7485 here.

SKIL TS6307-00

Features

- Blade guard and pawl included

- Telescoping rack and pinion fence system

- Integrated folding stand

- Parallel blade adjustment

- Dust collection port elbow

- Cast aluminum heavy duty table

- Comes with one 10 inch carbide tooth blade

- 3 Year Warranty

Specifications

- 15 amp, 4600 RPM motor

- 25.5 inch ripping capacity

- Accepts 10 inch table saw blades

- Max. Width of Dado cuts: 5/8 IN.

Overview:

If you’re looking for a good quality compact table saw that you can set up around your workshop easily then this might be the one for you.

This model features foldable legs that allow users to store it or place it anywhere in the workshop with ease. It also features a rack and pinion system for its fence and a 15 amp motor capable of providing 4600 RPM. Comes with a 10 inch 24T blade and dust collection system.

This is a great choice for woodworkers looking for mobility and to save space in a workshop.

Check out the SKIL TS6307-00 here.

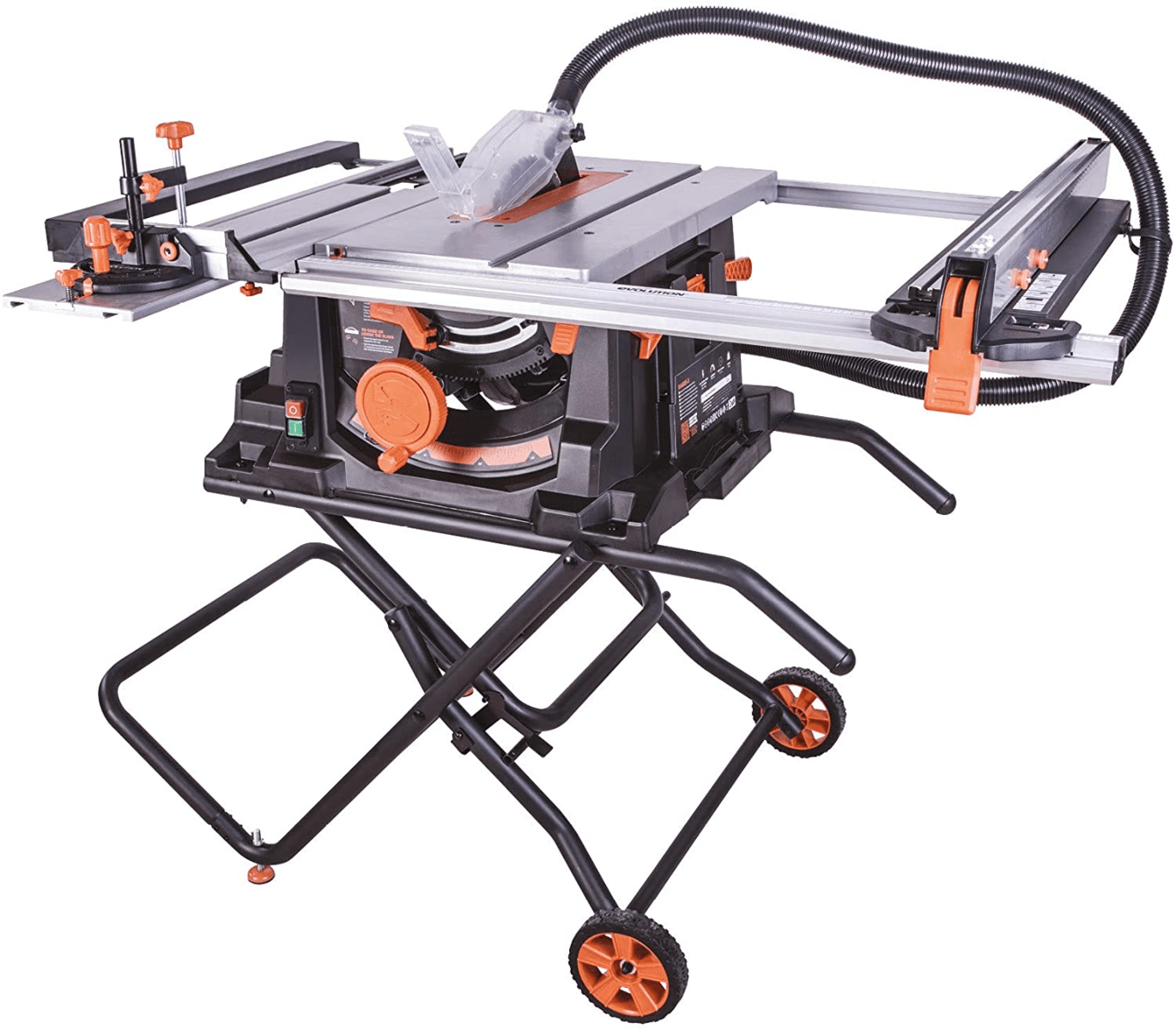

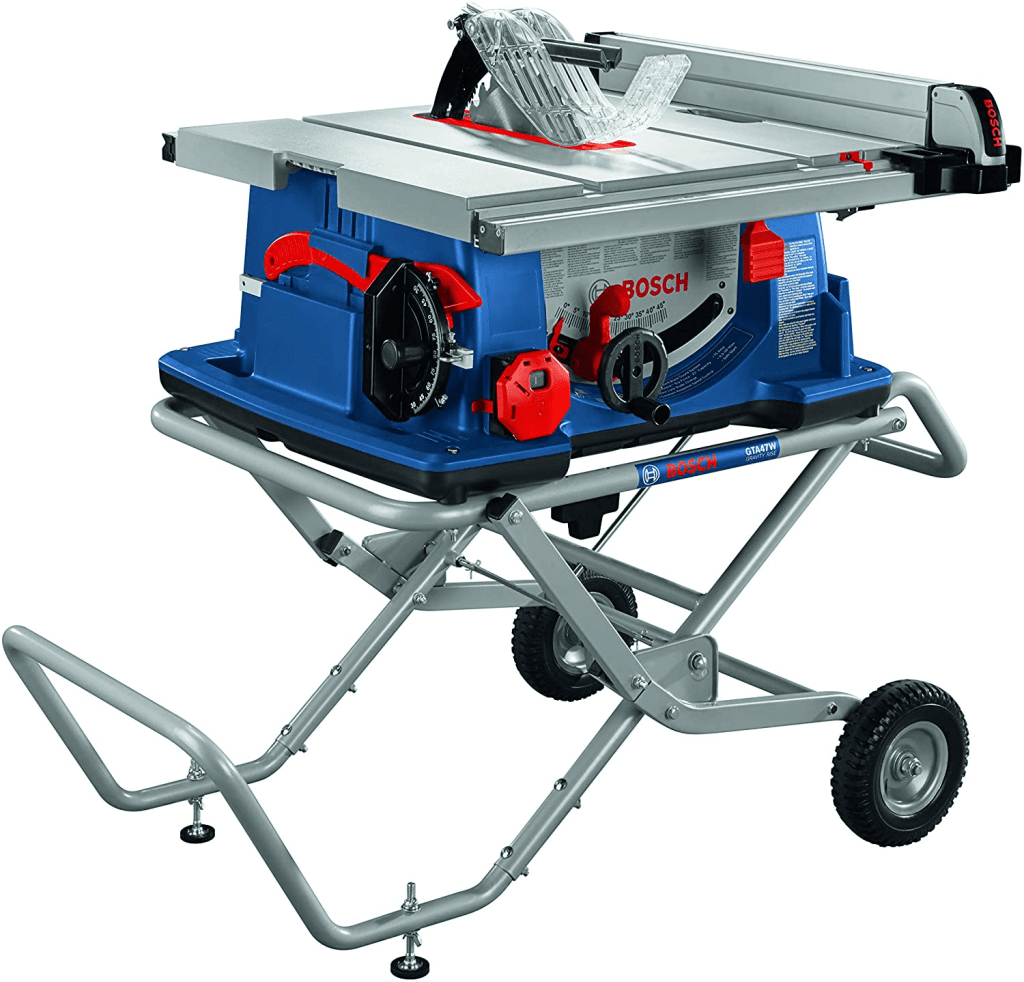

BOSCH 4100 XC-10 Jobsite Table Saw

Features

- Soft start feature

- Restart protection

- Square Lock rip fence

- Soft start circuitry

- Smart Guard System

- GTA47W gravity rise wheeled stand

- Comes with one 10 inch carbide tooth blade

- Built in accessory slots

Specifications

- 15 amp, 3650 RPM no load speed

- 30 inch ripping capacity

- 109 lbs

- 0 to 45 degree bevel angle range

Overview:

As with most Bosch power tools, this With its rolling stand, this entry level job site table saw is a great choice for woodworkers who need a table saw that is easy to haul out of a storage shed into a workshop or transport and move around a construction site yet still has enough cutting capacity for larger projects.

Its controls and features are easy enough for beginners to learn and it provides quality performance wherever you take it. It’s heavier than other table saws in this category but it’s still one of the best starter table saw models in the market today.

Its self aligning fence is a handy feature that can easily be moved and locked in the required position. Its 15 amp motor provides 3650 RPM for rip cutting and cross cutting of fine and rough materials. This model also comes with multiple safety measures such a riving knife, anti-kickback pawls and a blade guard as part of its Smart Guard System. A folding stand variant is also available.

This portable table saw is a great choice for beginners who need to carry their tools with them where they’re needed. Dust collection system products are available for this model but are sold separately.

Check out the BOSCH 4100 XC-10 here.

Metabo HPT – C10RJ SM Jobsite Table Saw

Features

- Comes with 10 inch 40T saw blade

- Features soft start and electric break

- Has foldable legs and wheels

- 2 year warranty

- Comes with variety of blade wrenches

Specifications

- 15 amp, 4500 RPM

- 35 inch rip capacity

- 0 to 45 degree bevel range

- 96 lbs

This job site model is a reliable tool that gives impressive power, cutting capacity and precision while mounted on a mobile base.

It’s a user-friendly table saw that has features such as a “fold & roll” design of its base for an easy setup and breakdown, a telescoping table extension that has a 35 inch rip capacity and a powerful 15 amp motor capable of 4500 rpm.

It also comes with a miter gauge and a 10 inch 40 tooth blade along with multiple safety features.

For the price, you get a product that provides quality performance on the go.

Check out the Metabo HPT – C10RJ SM here.

Delta 36-6013

Features

- Heavy Duty Fence Construction

- 5 year warranty

- Dust port

- 13/16 in. X 8 inch stacked dado blade capacity

Specifications

- 15 amp, 5000 rpm

- 59.9 lbs

- 25 inch rip capacity

If you’re looking for a professional quality table saw that provides accurate cuts without putting much of a hole in your pocket, this might be a good choice for you.

The heavy duty one piece rail system, along with the newly designed fence system allows for consistent precision cuts. The table saw’s fence incorporates a special design allowing you to cut narrow pieces of stock. This model has a 25 inch rip capacity and 3-1/2 inch maximum cutting depth at 90 degrees and 2-1/2 inch at 45 degrees. It can take a stacked dado blade and it also comes with a 2.5 inch dust port for an easier dust collection system.

All these features and its quality performance make this model a great addition to this list.

Check out the Delta 36-6013 here

Before You Buy

Before you go on to buy a table saw, here are some features you, as a buyer, should know about.

Types of Table Saw

There are two main types of table saw you should know, a stationary and portable table saw. Portable variants are designed to be lightweight and mobile. These are often cheaper but less powerful. Stationary table saws are generally used in dedicated workshops because of their heavier build. These are more powerful but heavier and definitely not something you want to keep moving around very often.

You may have noticed that we did not include any stationary table saws among our top picks. This is for the consistency of the article. We only included portable saws because portable models are generally the more budget friendly option compared to most table saws, especially stationary counterparts.

Portable Table Saws:

Benchtop table saw

As the name suggests, these saws are to be placed on top of a work table although some models come with a stand that you can mount it on. They’re lightweight in design and are often used by hobbyists. They aren’t necessarily mobile but are lightweight enough for the average person to carry around short distances.

Their motors are not as powerful or as quiet but still offer good power for their size. They offer an adequate but limited rip capacity and bench space. It’s good enough for most tasks but you might have a hard time with larger projects.

Compact table saw

These are typically larger than benchtop saws and have a built-in stand to allow for more stability. These are commonly bought by enthusiasts and tradesmen for their sturdier build.

Models often come with a sliding miter gauge, a built-in sled and foldable or collapsible table legs among other features. These are somewhat still limited in rip capacity but are nonetheless, still very capable.

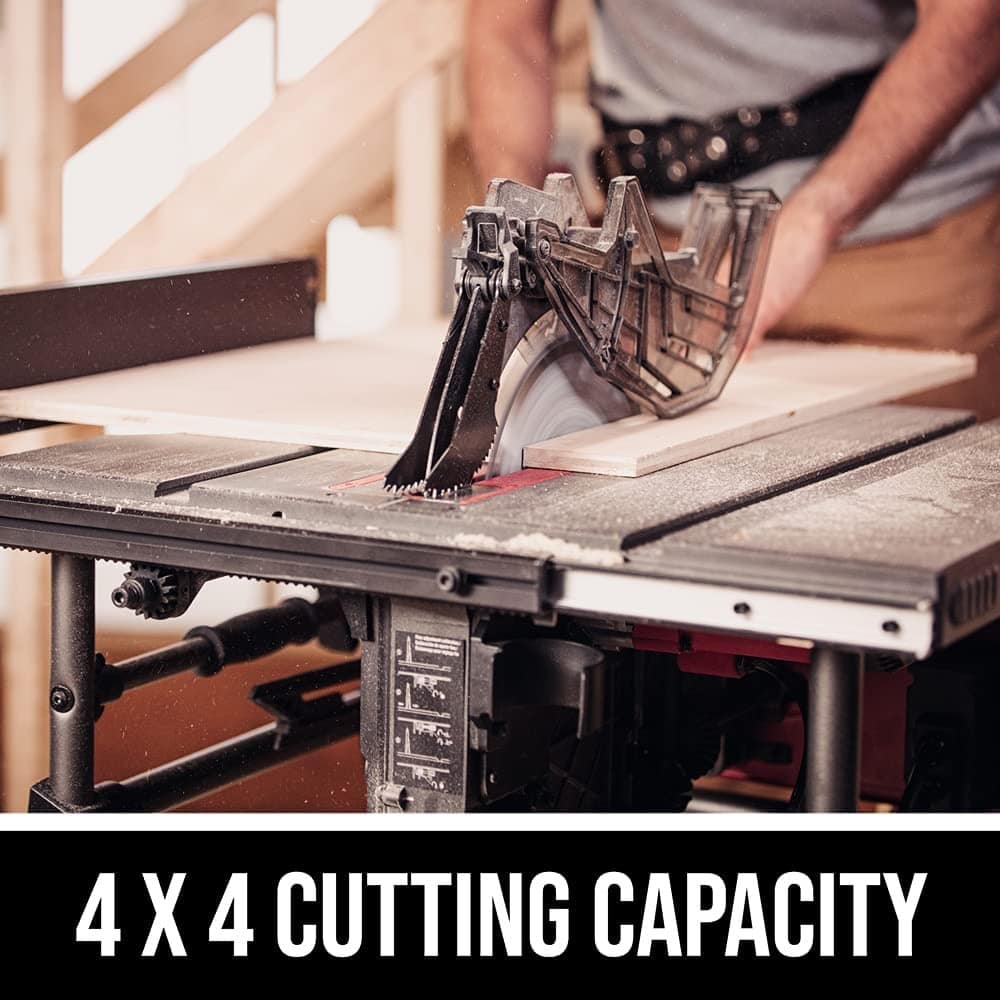

Jobsite table saws

A jobsite table saw is designed to be easily moved in and out of construction sites while still being durable, powerful and stable. They are one of the most popular categories of table saw today.

Jobsite saws are the ultimate balance between mobility and effectiveness. These are often called contractor saws because they often see use with contractors but they are in fact different from an actual contractor saw.

They provide greater mobility with built in rolling stands and feature greater rip capacities than benchtop models. Accessories like a longer rip fence, riving knives, push sticks all increase efficiency.

Stationary Table Saws:

Contractor Table Saws

A contractor table saw, also called an open-stand table saw, is large and heavy in size. They were originally built to be smaller and more portable versions of a cabinet saw and were very popular with professionals and amateurs alike. When jobsite models became more popular however, these started to be used more as stationary saws.

The motor is positioned on a hinge to the rear of the saw and can produce 1 to 2 hp (750 to 1500 W). This is more than enough power to cut through most material. The onboard motor adds a lot of weight but lessens vibrations. These also feature larger rip capacities compared to their smaller relatives but are significantly more expensive.

Hybrid Table Saws

A hybrid table saw combines features from a cabinet saw and a contractor saw. A hybrid table saw is similar in motor size to a contractor model and has a cabinet stand, internal motor mount and a trunnion assembly for support.

A hybrid saw is basically a contractor saw wrapped in an enclosed cabinet.

Because a hybrid table saw has a 1 1⁄2- to 2-hp motor inside the cabinet, the shorter drive belt makes for more efficient power transmission and less vibration than a traditional contractor saw while still plugging into a 120-volt outlet. The enclosed cabinet also aids dust collection.

Cabinet Table Saw

These table saw variants are the most durable and most expensive of the bunch and because of that, they can be found in professional workshops and factories.

Most cabinet saws are built with a cast iron table and steel. They’re durable, robust and made to last. Their induction, belt-drive motors make these a powerful table saw. They run belts in parallel to produce 3 to 5 hp (2.24 to 3.73 kW), single-phase.

At industrial sites, it’s not uncommon to see cabinet saws with motors that produce 5 to 7.5 hp (3.73 to 5.22 kW), three-phase. This requires a hard-wired, 240 volt dedicated circuit. They also have wider rip capacity with most models allowing upto 50 inches. These are meant for dedicated workshops due to their size and weight (some models can reach upto 600 lbs) and offer more power than its other counterparts.

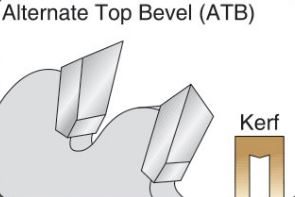

Blade Types

There are four basic blade types based on the shape of their teeth. These are the flat top grind (FTG), alternate top bevel (ATB), combination (ATBR) and the triple-chip grind (TCG). Here’s a quick breakdown of which one does what.

FTG blades have teeth whose top edges are flat, hence the name. Also called rakers, these cut wood like a chisel. They’re fast cutting and durable but aren’t known for producing a clean surface. They’re designed to rip, sawing with the grain.

ATB blades have teeth that are angled across the top edge with each tooth leaning in the opposite direction. This causes it to shear the wood fibers cleanly in a slicing motion. The steeper the bevel angle, the cleaner the cut but the faster they dull. Most 40 tooth ATB blades are marketed as “all purpose blades”.

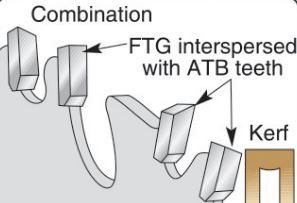

Combination blades consist of 50 teeth arranged in sets of five, with four ATB teeth followed by a raker tooth and a chamfered tooth. The chamfered tooth roughs out the cut while the following FTG tooth cleans it up. This tooth configuration is meant for cutting through dense materials. Combination blades are also considered as all purpose blades.

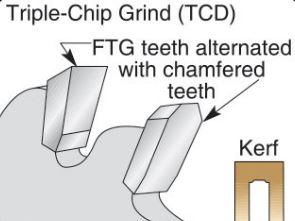

CG teeth alternate between a raker tooth and a chamfered tooth. The chamfered tooth roughs out the cut while the following FTG tooth cleans it up. These are also good dense materials.

Rip Fence

A rip fence is a cutting guide. It sits to the right of the table saw and is used to keep your board in place as you make a rip cut along the grain. For cross cutting boards, you’ll need a miter gauge.

The rip capacity is also important. To measure rip capacity, you measure the distance from the saw blade. Then, measure the greatest distance the fence travels to the right of the blade. That’s your rip capacity.

Miter Gauge

A miter gauge holds and guides material at a specific angle to make a precise cut. The locking mechanism pivots from 45 to – 45 degrees.

Motor

Belt Drive

Belt driven saws are more powerful and are found in stationary table saws. Belt-drive configurations have a pulley and v-belt system in place. The belt then transfers the power to the blade. These produce 3 to 5 HP and are made to cut through dense material.

Besides being more powerful, these are also a lot quieter than direct drive motors and vibrate less.

Direct Drive

These are often found in portable table saws. These produce less power but require less maintenance. This configuration is where the blade is driven directly by the motor, transferring all the power produced to the cutting blade.

Safety Features

In the woodworking business, table saws are potentially very dangerous. A circular saw or dado blades spinning at high speeds can easily sever or lacerate a finger. It’s very important to know the safety features in place to prevent any accidents from happening in woodworking shops.

For more safety tips while using a table saw, please read the OSHA guidelines here:

Riving Knife

A riving knife sits behind the blade and adjusts with its height. This prevents material from jamming into the back of the blade which could cause a very sudden and violent jolt commonly known as “kick back”.

Anti-Kickback Pawls

These are table saw attachments that reduce the kickback while operating the saw.

Push Sticks

These are pretty straight forward, a push stick is a device you hold the material and feed into the saw. These extend your reach and give your hand some leeway in case of kickback.

Blade Guard

These protect you from debris and from kick back. Some come with a vacuum duct for dust collection but some people resort to a riving knife for better visibility.

Maintenance Tips

- Clean all sawdust that might accumulate in the nooks and crannies around the machine with a brush and a vacuum.

- Lubricate moving parts such as the adjustment mechanisms

- Clean the cutting blade

- Keep the tabletop clean of dust and debris after every use

- Check the blade raising and tilt mechanisms for looseness or binding

Summary

Table saws are a great investment for woodworkers and being economical about that investment is a smart move.

Knowing what you need is just as important as how much you’re willing to spend and we hope that the article above has helped you in making an educated decision.

Other Affordable Table Saws

We’ve researched dozens of different models to put on this list. We factor in the price, availability and quality of the products so as to make this list as updated as possible.

Here are some other models you might consider checking out.