Quick Introduction to Sanding Belts

In workshops across the globe, belt sanding machines are a common sight. Belt sanders are a multi-purpose power tool that use abrasives for sanding wood, leveling, freehand rounding, shaping wood surfaces, rough surfaces or edges. They can also be used for masonry and for our topic for today, metalworking. In this article, we’ll be focusing on the various sanding belts used for metalworking, how they work, what you should know and which ones we recommend.

Belt sanders use a pair of drums that have a loop of sandpaper mounted and work in a similar fashion to that of a conveyor belt. They come in benchtop, stationary and handheld variants that all use a loop of sandpaper. This loop of sandpaper is connected on both ends and forms a continuous belt. This explains why these commonly go by the name, sanding belts.

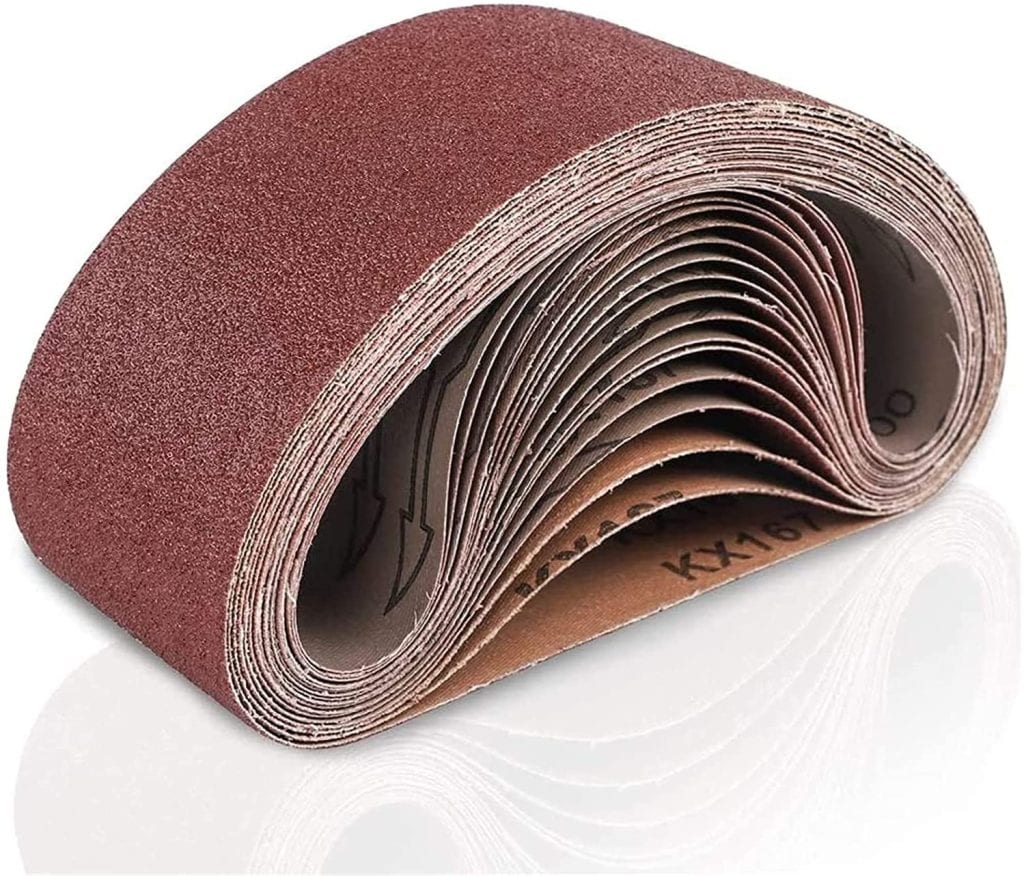

Sanding belts come in various lengths, grit levels and can be made with different kinds of abrasive material to get the desired finish. In metalworking, sandpaper is used for different tasks such as paint removal, polishing, grinding, deburring and finishing. These are commonly used on small to medium sized projects such as knife making, decorative pieces, refurbishing and furniture. While technically you can use sandpaper to manually sand a workpiece, mounting a sanding belt on a belt sander gives you more versatility and efficiency.

Now that you have a general idea on what sanding belts do and how they are applied in metalworking, let’s take a deeper dive into what they’re all about and what to look for.

A Quick Comparison of Our Favorites

| IMAGE | PRODUCT | |

|---|---|---|

Editor's Choice  |

| View On Amazon →Read Our Review |

Runner-up  |

| View On Amazon →Read Our Review |

|

| View On Amazon →Read Our Review |

|

| View On Amazon →Read Our Review |

|

| View On Amazon →Read Our Review |

Table of Contents

| Topic |

| Quick Introduction to Sanding Belts |

| Best Sanding Belt for Metal Buying Guide • Different Applications • Types of Abrasive Grains • Grit Level / Sizes • Tips |

| Our Recommended Sanding Belts |

| Conclusion |

Sanding Belts for Metal Buying Guide

Different Applications Abrasive Sanding Belts in Metalworking

Before you buy sanding belts, it’s important to know what types of sanding tasks you can accomplish with them. Here are some of the most common sanding tasks you should know about when using a sanding belt for metalworking.

Sharpening

While the most common sharpening tool is a grindstone or whetstone, sanding belts have seen growing use among knife makers because of the broad range of grits, ease of use and cheaper price tag.

Sanding belts can be easily swapped out for lighter or heavier grits allowing for a smoother finish. Belt sanders used in sharpening use thinner sanding belts and are often compact enough to fit in most workshops.

Grinding & Deburring

Grinding metal using a belt sander instead of a grindstone has its advantages. For one, it’s easier to turn a workpiece along a sanding belt because of its consistently flat surface whereas a grinding stone may degrade over time.

It’s also cheaper to replace and swap low grit sanding belts for grinding. Some brands offer metal grinding sanding belts that prevent the build up of metal fillings making them last for longer. For metal grinding, the best type of sanding belts to use are those made with zirconia and ceramic.

Polishing

Polishing metal workpieces is one of the most common uses of belt sanders in metalworking. Clearing scratches and blemishes from metallic surfaces usually starts with lower grits and gradually uses higher grits as the surface smoothens.

While manual polishing is popular, belt sanders are more efficient and can polish larger surfaces with minimal labor. There are chemical agents such as ammonia which help in polishing metallic surfaces which greatly make the task easier.

Buffing & Finishing

The next step after polishing a metallic surface would be to buff it for the desired finish. Buffing sanding belts are commonly made with softer materials such as cloth and use a chemical agent to aid in the process.

Similar to polishing, manually buffing metallic surfaces is popular and often the preferred method of getting a smooth finish. However, using a buffing sanding belt does make the job easier, more consistent and faster especially on larger surfaces.

Types of Abrasive Grains

Aluminum Oxide Belts

This is one of the most common materials for sand paper and is used for general purpose sanding tasks. Sanding belts made with aluminum oxide are popular due to their lower cost compared to other materials, wide applications and grit range. When used on metallic surfaces, aluminum oxide sanding belts do not last as long as some other materials but its low cost make it easily replaceable.

Silicon Carbide Belts

When used on sanding belts, silicon carbide can have very coarse grits to very small micro grits. The very coarse grits makes it great for rough applications such as masonry, rust removal and other heavy duty sanding tasks. While the micro grits make it a great choice for polishing and surface preparations for painting. Silicone carbide sandpaper is also commonly used for wet sanding methods which prevent fine dust or metallic particles from causing issues. Because of the nature of silicone carbide, sandpaper made with this material does not last for very long and often wears out faster. This is regarded as worth it by many when you consider the specialized tasks and better finishes that silicone carbide sandpaper provides.

Alumina-Zirconia Belts

Also called zirconium, this material is great for heavy duty sanding tasks such as deburring and grinding. Zirconium sanding belts commonly come in coarser grits and are capable of withstanding higher pressures. Because of their heavier duty applications, Zirconium sanding belts have cloth lining to provide more support.

Ceramic Belts

Sanding belts made with ceramic are considered to be the most durable and reusable. These are used in rough sanding tasks such as rust removal and for grinding high carbon steel. Ceramic sanding belts last significantly longer than any other material used for sandpaper because of their structure. They are also more expensive and often come in only lower grits.

Grit Levels / Sizes

One important factor you should know about before buying a sanding belt are the levels of grit. Grit refers to how coarse the abrasive particles on the surface of a sandpaper is. This can be separated into two categories, low grit (macrogrit) and high grit (microgrit). The lower the grit size of a sandpaper, the coarser the abrasive particles on its surface. Sandpapers will usually have the grit size at the back along with the brand name. Here’s a comparison chart for the standard CAMI grits.

Macrogrits

| Grit Rating | Ideal Uses |

| 24, 30 & 36 grit | Very coarse sandpaper used for grinding, deburring and quick material removal. |

| 40 to 50 grit | Coarse sandpaper used for heavy sanding tasks such as paint removal |

| 60 to 80 grit | Medium grit sandpaper used for surface preparations such as varnish removal. Also used as grip tape. |

| 100 to 120 grit | Fine grit sandpaper used for further surface preparations. |

| 150, 180 & 220 grit | Very fine sandpaper for light sanding tasks. |

Microgrits

| Grit Rating | Ideal Uses |

| 240 grit | Very fine sandpaper similar to 220 grit. |

| 320 to 360 grit | Extra fine sandpaper used for surface polishing tasks. |

| 400, 500 & 600 grit | Super fine sandpaper used for further polishing and finishing tasks. |

| 800, 1000+ grit | Ultra fine grit sandpaper for final touches and light scratch removal. |

Tips for Using Sanding Belts on Metal

Here are some quick tips that you can apply when using a sanding belt for sanding metal. These will hopefully make you more efficient at sanding metal.

- Start at low grits and gradually go higher. This is to ensure that the metal surface you are sanding has an even finish that can then be buffed or painted.

- Take occasional breaks to prevent overheating and tearing. Because of the tremendous amount of friction generated by sanding belts, it’s recommended that you take short breaks to stop the sandpaper from tearing or burning because of the heat. This also helps extend the lifespan of the sandpaper.

- Clean the surface before sanding. Before you begin sanding, you should try to remove any oils or grease from the metal surface. You can use a cloth to wipe the workpiece down of any dirt or oils. This is to prevent the sanding belt from clogging up and ensures that you get the desired effect every time.

- Make sure you get the right dimensions. While most belt sanders will take similar sized sanding belts, it’s important to know the specific size for your current machine. There are methods to resize sanding belts in case you need a specific size but we recommend double checking your machine before investing in a pack of sanding belts.

- Use a shop vacuum and wear protective equipment. Sanding any type of metal will generate a lot of very small metal particles which can cause serious issues if they get into your eyes or if inhaled. Safety goggles and a filtered mask should be worn at all times when sanding metal. A shop vacuum would also significantly lessen the metal particles left in the air. You should not use a shop vacuum when grinding however as this can be a cause of fires.

- Use the appropriate abrasive material for the metal to be sanded. It’s important to know the properties of the type of metal you plan to work on.

Our Recommended Sanding Belts

Red Label Abrasives 4×36 inch pack | Specs: • Material: Ceramic • Finish: Very coarseIdeal • Uses: metal grinding, heavy duty sanding • No. of Sanding Belts: 3 piece pack • Included Grit Sizes: 36 grit |

Red Label Abrasives 2×42 inch pack | Specs: • Material: Nylon mesh fibers • Finish: Fine to Very Fine • Ideal Uses: buffing, cleaning • No. of Sanding Belts: 3 piece pack • Included Grit Sizes: n/a |

S SATC 4×36 inch Sanding Belt Pack | Specs: • Material: Aluminum Oxide • Finish: Medium to Super fine • Ideal Uses: Surface preparations, polishing, sharpening • No. of Sanding Belts: 12 piece pack • Included Grit Sizes: 60, 80, 120, 150, 240 & 400 grit |

Sackorange 4×36 Sanding Belt Pack | Specs: • Material: Silicon Carbide • Finish: Fine to Ultra fine • Ideal Uses: sharpening, finishing, polishing, wet sanding • No. of Sanding Belts: 6 piece pack • Included Grit Sizes: 120, 240, 400, 600, 800 & 1000 grit |

Red Label Abrasives 1×30 inch pack | Specs: • Material: Ceramic • Finish: Very Coarse to Fine • Ideal Uses: sharpening, rough sanding, grinding • No. of Sanding Belts: 6 piece pack • Included Grit Sizes: 36, 40, 60, 80, 100 & 120 grit |

Conclusion

And there we have it, everything you need to know about sanding belts for metal and our most recommended sanding belts. We hope that this article taught you a thing or two about sanding belts and that you find which one is the best for you. Thank you dear reader and happy sanding!