If you often work on DIY projects like me, you know how important it is to have the right tool. Versatility is among the top buying factors, especially when handling different materials. Below, I will cover a multi-function tool called a die grinder.

A die grinder is a handheld power tool compatible with several attachments. These accessory bits attach to the grinder by a collet, which is a small holding device. Each one suits a specific application, making the die grinder a versatile tool.

A die grinder is a popular tool in metalworking, but it is also ideal for woodworking and other industrial tasks. This article covers a die grinder in more detail. You will learn about its definition, applications, and types below.

What Is a Die Grinder?

A die grinder is a portable, handheld tool for grinding and polishing different materials. It features an encased motor and a rotating spindle that accepts various bits. These attachments vary in size and purpose to suit a wide range of industrial tasks. However, they all move at high speeds to remove material from the workpiece.

A die grinder is originally designed for molds and dies, hence the name. Today, this versatile tool is popular for cutting and smoothing metal sheets. However, it can also shape wood, plastic, and other materials when you use the appropriate bit attachment.

A die grinder functions similarly to other rotary tools. It uses either compressed air or electricity to power the motor. I’ll talk more about these two types of die grinders later.

How Does a Die Grinder Work?

A die grinder uses a motor powered by compressed air or electricity to drive the spindle. This component has a collet chuck, which is a small cylindrical device, to hold various accessories. These include bits, grinding wheels, and carbide burrs, among many others.

The spindle rapidly rotates these accessories to remove material from the workpiece. With the right tool bit, the die grinder can also cut, drill, polish, and shape various objects. It is a popular tool for metalworking, woodworking, and other industrial applications.

Besides the accessory bit, the rotations per minute (RPM) of the die grinder can determine the tasks it can handle. For instance, a higher RPM is best for polishing and other detailed work. Meanwhile, a lower RPM is ideal for heavy-duty grinding. That is because it delivers higher horsepower and more torque.

What Do You Use A Die Grinder For?

A die grinder can perform many tasks when used with the proper bit attachment. Below are some common uses of this multi-functional tool.

Polish Metal Surfaces

A die grinder with polishing wheels can clean and buff various metal objects. Whether you’re working on an automobile or a simple metal sheet, it can give you a smooth surface in no time.

There is no need to manually clean the metallic chips from the workpiece. Save time and effort when you use a die grinder.

Grind Dies

The original purpose of a die grinder is to grind dies, hence the name.

This compact tool can easily match the profile and size of various tools. It also delivers high-speed rotation and precise control. These benefits make the die grinder suitable for metal stamping, plastic molds, and other types of casts.

Remove Rust and Paint

Rust can be challenging to remove on metal surfaces. Once it appears, it can quickly spread throughout the entire surface. It can lead to deterioration over time.

Fortunately, a die grinder with a wire cup brush can remove rust on metal surfaces like heavy machinery or a car. It can also strip off stubborn paint and other polishes. These can be difficult to remove with sandpaper.

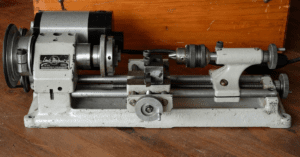

Cut Metal Sheets

Die grinders can divide metal sheets into two when using special cut-off wheels. They can also cut down metal bolts.

However, it is essential to choose the right bit attachment for cutting metal. Select abrasive cut-off wheels when handling soft metals like aluminum and copper. Opt for diamond-cutting wheels instead to penetrate hard metals, such as steel.

Smoothen Weld Lines in Metal

Excess weld lines on the metal can be unsightly and lead to the material breaking off. Fortunately, a die grinder with a burr attachment can fix these defects and produce a smoother surface.

Carve and Sand Wood

Burr bits on die grinders can help you carve wood into various shapes and sizes. Their compact design enables you to produce intricate designs.

Die grinders can also work as a sander. They can smoothen wooden surfaces to prepare them for paint and other finishes.

Shape Plastics

Besides metal and wood, die grinders can also shape plastic.

However, note that this material is soft and susceptible to melting. Use a fine burr attachment and work at a slow speed to prevent frictional heat.

What Are the Different Types of Die Grinders?

Die grinders are classified into two types based on their power source. Below, we will compare pneumatic vs. electric die grinders.

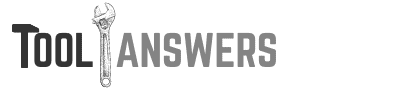

Pneumatic Die Grinder

This type of die grinder uses compressed air to drive the motor. As such, the tool must always be connected to the compressor to work. It gives you continuous power as long as it is properly maintained and lubricated.

Pneumatic die grinders are also more powerful with heavy torque. They can quickly remove lots of material from the workpiece. They are also suitable for other heavy-duty tasks, like stripping off rust and paint.

Plus, they tend to have better efficiency. Excessive heat is not an issue with these air-powered grinders.

However, as previously mentioned, these pneumatic die grinders need bulky compressors to work. They are difficult to move. They can also prevent you from reaching the nooks and crannies of the material.

But if you prefer reliable performance to portability, then air power is the way to go.

Electric Die Grinder

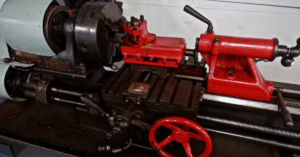

As their name suggests, these die grinders have an electric motor with or without a battery.

Corded electric die grinders are plug-and-play tools. This type is generally an inexpensive die grinder and they are convenient to use in most workplaces.

Meanwhile, cordless electric grinders offer excellent mobility. They are easy to maneuver in tight and hard-to-reach areas.

However, an electric die grinder is only suitable for small-scale applications. It also tends to overheat when used for long periods, ultimately affecting performance.

That said, an electric die grinder is still an attractive option for its portability and affordable cost.

Straight Die Grinder vs. Angle Die Grinder: What Is the Difference?

You can also categorize grinding tools based on their design.

Straight die grinders are exactly as they sound—they have a long, straight body. They look like large screwdrivers. Despite their size, they can reach small areas and tight corners. These die grinders can create intricate patterns and shapes on various materials.

On the other hand, angle grinders have their head perpendicular to the shaft. They create a 90-degree angle that makes it easy to cut through larger materials. They can also quickly polish broad surfaces.

Choosing between a straight die grinder and an angle grinder will depend on the task and your preference. The former is best for precise and intricate work. In contrast, the latter is suitable for more demanding applications.

Frequently Asked Questions

Is a die grinder the same as a Dremel tool?

While both are versatile handheld tools, die grinders are different from a Dremel tool. They are often larger and more powerful with greater torque than a Dremel rotary tool. They are suitable for heavy-duty tasks like grinding metal and removing rust.

Meanwhile, a Dremel Multi-Tool has a small and portable design. It is compatible with a wide range of accessories, making it more versatile than a die grinder. It is best for smaller, intricate tasks like crafts and woodworking.

Can you use a die grinder as a cut-off wheel?

You can attach a cut-off wheel to a die grinder tool. Doing so can help you cut sheet metal, bolts, and welds.

However, be careful when using cutting wheels with a die grinder. This tool lacks a wheel guard that protects your hand from the sharp blade. One mistake can be very dangerous. Wear safety gloves to lower the risk of injuries. You may also want to minimize distractions when using a die grinder with a cut-off wheel.

How to change a die grinder bit?

Replacing the die grinder bit is relatively straightforward. All you will need is the wrenches that come with the package.

Place the first wrench on the grooves in the collar portion of the die grinder. This will secure the shaft and prevent it from turning.

Then, use the second wrench to turn the collet nut. Doing so will loosen the bit.

Once it is loose, you can take it out of the collet. Be careful when removing it because you’re dealing with sharp material.

Store the old bit in a secure place. Then, grab the replacement part and attach it to the die grinder.

Use the wrench again to tighten the grinding attachment. And you’re done—you successfully changed the die grinder bit.

Conclusion

Die grinders are among the most versatile tools for industrial applications. They have a rotating spindle and a collet chuck that holds the cutting bit. These accessories vary in design and size that are ideal for grinding, polishing, and sanding, among other tasks.

Do you have other questions about this multi-function tool? Feel free to reach out via our contact page!