Plasma cutters can vary greatly, and whether you are new to metalworking or not, there are some key features to consider. With those features, and cost in mind, we have found the best plasma cutters for your next project.

The best overall plasma cutter in our top picks is the PRIMEWELD CUT60P, because it’s powerful, user friendly, and comes with a kit of parts you’ll need to complete the job.

Of course, your project may require specific features in a plasma cutter, so we included three great alternate options, plus a buying guide to help you understand the key elements in a plasma cutter before making your purchase.

Below is a short list of our top picks and detailed reviews of each, so you can make a quicker decision and get on with the fun stuff – metalworking.

Best Plasma Cutter Comparison

| IMAGE | PRODUCT | |

|---|---|---|

Overall Best  |

| View On Amazon →Read Our Review |

Second Best  |

| View On Amazon →Read Our Review |

Best Kit  |

| View On Amazon →Read Our Review |

|

| View On Amazon →Read Our Review |

Table of Contents

Quick Introduction to Plasma Cutters

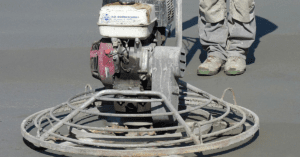

If you’re looking for a tool that’ll make short work out of metalworking projects like cutting through steel without making a mess or too much noise, there’s not much that does the job quite like a plasma cutter.

Plasma cutters are advanced machines that use superheated plasma to cut through metal. These are commonly used in many industries worldwide from automotive restoration, industrial construction and scraping. There are different types of plasma cutters for different industries which can make it difficult for newcomers to figure out which one is better suited for their needs. Smaller versions of plasma cutters have even been made for use in DIY workshops and will be the main focus of this article.

If you’re new to the world of plasma cutters and are looking for a place to start, look no further because we’ll be going over the best plasma cutters we’ve found for workshop use and a breakdown of the basics of plasma cutting below. By the end of this article, we hope that we’ll have taught you something new about plasma cutters and that you have a better grasp on which one is best for you.

So without further adieu, let’s get to the best plasma cutters and what they’re all about!

Best Plasma Cutters Reviewed

Overall Best Plasma Cutter:

PRIMEWELD CUT60P

Overview:

This 60 Amp plasma cutter from PrimeWeld is a powerful and user-friendly option with a slew of features such as blowback start technology, dual voltage options with adapters and a duty cycle of 60% that’ll earn its place at any workshop.

The PrimeWeld CUT60P is a portable plasma cutter perfect for professionals on the go or jobs and projects at home. It features a PT60 blowback pilot torch for use on CNC cutting tables and is designed for cutting stainless steel, mild steel and aluminum.

It also comes with a continuous pilot arc for cutting through metals such as

grating, mesh or perforated steel. These two options gives users

more versatility and ensure that you get the job done with ease.

The PrimeWeld CUT60P comes with integrated safety features such as overcurrent protection and overheating protection along with being built to be sturdy enough to withstand jobsite abuse. PrimeWeld also offers users after-sales assistance such as customer support and a 3 year warranty.

Check out the PrimeWeld CUT60P plasma cutter here.

| Plasma Cutter Specs: | Plasma Cutter Features: |

| – Ideal PSI: 55 – 75 psi – Output Range: 20 – 60 Amps – Duty Cycle: 60% at 60 Amps – Dimensions: 20x11x19 inches – Weight: 34 lbs | – Dual 110/240V input – CNC compatible – Overcurrent protection – Overheating protection – Digital display – Low maintenance – 3 year warranty |

Second Best Plasma Cutter:

Lotos LT5000D

Overview:

This plasma cutter offers users fast metal cutting action in a compact profile.

The Lotos LT5000D plasma cutter is a great tool to have in any fabrication workshop. It uses superheated compressed air to cut through stainless steel, alloy and aluminum providing a safe and cost effective solution. It features a 10 – 50 Amp output and is powerful enough to make a clean cut through half an inch of material.

The LT5000D is compact and fast to set up because of its pre-installed NPT type D plug and air filter which connects directly to an air compressor giving users great cutting performance a minute out of the box. It’s also a lower maintenance and safer solution making it a great choice for homeowners with metalworking hobbies or professionals looking for a capable tool to bring from job site to job site.

Check out the latest pricing for the Lotos LT5000D.

| Plasma Cutter Features: | Plasma Cutter Features: |

| – Severance Cut: 3/4 inch – Ideal PSI: 65 psi – Output Range: 10 – 50 Amps – Duty Cycle: 60% at 50 Amps, 110V / 60% at 50 Amps, 220V – Dimensions: 15x6x12 inches – Weight: 26 lbs | – Advanced cooling system – Pulse width modulation technology – Dual 110/240V input – Quick setup – Rugged construction – 1 year warranty |

Best Plasma Cutter Kit:

Reboot RBC5000D

Overview:

This plasma cutter kit from Reboot has a wide array of applications in the field of fabrication and metalworking. From cutting through sheet metal, metal pipes, bars and stainless steel, there isn’t much this plasma cutter can’t cut.

The Reboot RBC5000D plasma cutter makes quick cuts on metal with the help of its high output and PSI range. This kit conveniently comes with the PT31 cutting gun, a ground clamp, a transparent hose with clamps, electrodes, copper nozzles and a pressure valve for adjusting air pressure. Additional features include a digital display, a scale which suggests the appropriate PSI for a certain thickness and waterproofing around the machine for added safety.

All meant to give the user more options, flexibility and extending the tools lifespan. Speaking of lifespan, the Reboot RBC5000D also comes with a 3 year warranty so that you can rest easy knowing Reboot has your back.

Check out the most updated price for Reboot RBC5000D.

| Plasma Cutter Specs: | Plasma Cutter Features: |

| – Severance Cut: 3/4 inch at 220/240V – Ideal PSI: 60 – 70 psi – Output Range: 20 – 50 Amps – Duty Cycle: 60% at 50 Amps – Dimensions: 19x11x13 inches – Weight: 21.3 lbs | – Dual voltage / Dual frequency – Durable design – Digital current display – PSI suggestion scale – Updated air pressure regulator – High Frequency – 3 year warranty |

Best Budget Friendly Plasma Cutter:

Hynade HYC45D

Overview:

This reliable cutter from Hynade is a budget friendly alternative for those looking for robust build quality, numerous attachments and quick cutting action in one package.

The Hynade HYC45D is a high frequency plasma cutter capable of cutting through .39 inches of material at full power. This plasma cutter is compact and lightweight making it great for use in and outside of workshops. It’s designed to cut through metallic surfaces such as aluminum, steel pipes and steel plating making it a great pick for automotive refabrication among other metalworking projects.

The Hynade HYC45D also comes with a handful of features that make it more convenient and user friendly. This includes a scale to choose the appropriate PSI for the thickness, a LED display that shows the power, consumables such as nozzles, an air hose, earth clamp, cutting torch and even an air regulator.

Most people look down on cheap power tools but occasionally, a good one such as this will come across your way. Hynade proves that good quality tools can be made for budgets of all ranges.

Check out the Hynade HYC45D plasma cutter on Amazon.

| Plasma Cutter Specs: | Plasma Cutter Features: |

| – Severance Cut: .2 in at 60 PSI, .39 in at 70 PSI in 230V – Ideal PSI: 60 – 70 psi – Output Range: 30 – 45 Amps – Duty Cycle: 60% at 45 Amps, 100% at 30 Amps – Dimensions: 12×5.4×9 inches – Weight: 14.3 lbs | – LED display – Folding handle – Compact design – PSI to thickness scale – Uses IGBT technology |

Bonus Plasma Cutters

Here are some plasma cutters that didn’t quite make our list but we thought deserved an honorable mention.

TOOLIOM 50A | Plasma Cutter Specs and Features: – Ideal PSI: 65 – 73 psi – Output Range: 40 – 50 Amps – Duty Cycle: 60% at 50 Amps – Dimensions: 16×6.3×11.8 inches – Weight: 13.42 lbs – LCD display – Non-touch pilot arc – Overload protection – Temperature control – Auto adapting voltage regulator |

PrimeWeld CUT50 | Plasma Cutter Specs and Features: – Severance Cut: ¾ inches – Ideal PSI: 65 psi – Output Range: 10 – 50 Amps – Duty Cycle: 60% at 50 Amps – Dimensions: 15x6x12 inches – Weight: 22 lbs – 3 year warranty |

Cuwiny 50 Amp | Plasma Cutter Specs and Features: – Severance Cut: .6 in at 240v – Output Range: 10 – 50 Amps – Duty Cycle: 60% at 50 Amps, 100% at 40 amps – Dimensions: 14.8×6.2×10.2 inches – Weight: 14.3 lbs – 1 year warranty |

Plasma Cutter Buying Guide

How does it work?

Plasma cutters are complicated tools that deal with high temperatures and were originally designed as an alternative to welding. Turns out, a plasma cutter does the job a little too well.

A plasma cutter works by using an electrical charge that super heats air or gas that then passes through a nozzle. This gas can be normal air, oxygen, nitrogen and argon among other gases. The electrical charge super heats the gas to the point where it transforms into another form of matter, plasma. The plasma is blown out of the nozzle at high speeds and forms an arc which then connects to the metal surface to be cut.

Because of how intense the heat can be when cutting, plasma cutters are only meant to be used in short bursts to let the machine cool down and prevent it from melting the consumables too quickly. Plasma cutting is one of the most effective ways to cut metal and is used across the world in different industries. Plasma cutters commonly see use in fabrication, salvage and scrapping operations, automotive repair or restoration and even large scale industrial CNC applications.

Types of Plasma Cutter Consumables

Plasma cutters can come with a wide array of attachments and accessories. Consumables are accessories that are meant to be replaced eventually because of the intense heat plasma cutters generate. Here are a few of the most common ones you’ll come across.

Swirl Ring

Swirl rings are made with ceramic or similar materials and as the name suggests, they swirl the plasma around the electrode and through the nozzle. This creates a much cleaner stream of plasma for more accurate cuts along with creating a cooling effect with the swirling motion.

Electrode

Electrodes are narrow pieces of copper that the electrical current will travel through. Its job is to focus the plasma stream along its length which ends at the nozzle and causes it to arc onto the metal workpiece. Because copper would normally melt in such intense heat, it’s common to have electrodes made with other stronger conductors such as tungsten or hafnium.

Nozzle

A plasma cutter nozzle serves the same purpose as with any other nozzle, it is used to constrict the gas into a tight stream creating a thin kerf. Plasma cutter nozzles are designed to handle different power ratings such as 40 Amps, 50 Amps, 80 Amps and onwards. Because of the intensity of the heat, these are some of the most replaceable consumables in a plasma cutter.

Shield Cap

A shield cap attachment is pretty straight forward. As the name suggests, this attachment is designed to protect the torch and its internal components such as the electrode from sparks or molten metal that might fly back as the plasma cutter is operating.

Retaining Cap

Essentially, a retaining cap holds all the components of the cutting torch together from the swirl ring to the shield cap. These are typically built with slightly thicker walls to protect the internal components from any outside factors such as dust, sparks and molten material.

Key Factors of a Plasma Cutter

Severance Cut

When using a plasma cutter, it is relatively easy to make clean cuts of differing thicknesses. A severance cutting depth refers to how far the plasma cutter will cut beyond a clean cut. Severance cuts have rougher finishes and require some cleaning up afterwards. There are several factors that affect the severance cut thickness of a plasma cutter such as how many amps you’re using, what type of metal you’re cutting through and the PSI being used.

Amperage

Also called the output range, this refers to the amount of power your plasma cutter can throw out. While you could use the max Amp setting on your plasma cutter and be done with it, sometimes max power isn’t the solution. When used on thinner metals, too much power could leave the metal melted or warped. Using the max power setting also isn’t good for the lifespan of consumables as it will cause them to wear out much faster. Plasma cutters let you adjust the amperage to cut a specific thickness or a specific type of metal that might have a lower or higher melting point.

Duty Cycle

On a plasma cutter, the duty cycle refers to the percentage of time it can safely operate per period at a set amperage. For example, a plasma cutter with a duty cycle of 60% at 50 Amps means that, at 50 Amps, it can cut for a period six minutes out of ten. The reasoning for having a duty cycle is to give the user a heads up on how much power they’ll have and for how long they’ll have it given the amperage.

So why can you only use a percentage of time at a given amperage?

It is considered a global standard that you should use a plasma cutter for at most, ten minute intervals at a time. This is to give the plasma cutter enough time to cool down between cutting periods. While you can use all of the ten minutes at a lower amperage, it is highly recommended that you do not run a plasma at full power for the whole ten minutes or more. If you do exceed the recommended duty cycle, you could run the risk of having your plasma cutter overheat and your consumables be damaged.

Recommended Air Pressure

The recommended air pressure on a plasma cutter refers to the manufacturer’s suggested PSI at which the machine should operate safely at. Air pressure is measured in PSI or pounds per square inch with most plasma cutters having a recommended PSI of anywhere from 50 – 75 PSI. Whatever PSI you set your plasma cutter to will affect things such as how long the plasma stream will be and how intense it’ll be.

Key Parts of a Plasma Cutter

Cutting Torch

This is the part of the plasma cutter that holds the consumables, the tube that the air will travel through and the trigger mechanism. The cutting torch is what the user will be holding during cutting sessions. There are different types of cutting torch depending on the manufacturer.

Air Regulator

On most plasma cutters, the air pressure is regulated through a small attachment located at the rear of the machine. These air regulators filter the air from contaminants such as dirt which could affect the quality of the plasma stream. It should be noted that most air regulators only remove the minimum amount of matter from the air. This is because most particles that get burned along the gas are not likely to change the quality of the plasma stream.

Earth Ground

Because of the high amperes used in plasma cutters to cut through metal, the ground clamp offers a level of safety for the internal components of the plasma cutter and to the user should any short circuits, surges or fluctuations happen. The earth ground is normally connected to the workpiece and if the workpiece is too small, then a neary unconnected piece of metal should also work.

Other Parts of a Plasma Cutter

Air Hose

The air hose is an optional attachment for plasma cutters should you choose to use gas in a pressurized tank. These connect directly to the plasma cutter usually at a port at the back of the machine.

Hose Clamp

Hose clamps are used to secure or fasten a hose over a fitting. Hose clamps prevent any fluid or gas from escaping and leaking.

FAQs

Q: How long should the consumables last on a plasma cutter?

A: On average, the consumables should last you around 3 hours worth of cutting when used properly. That being said, there are a lot of factors that can affect the lifespan of the consumables such as the power settings, which duty cycle you’re working at and even the type of air used.

Q: How many amperes do I need in a plasma cutter?

A: This depends greatly on what you’ll be using it for. If you plan to use it for metals such as hardened steel then you might want to go for plasma cutters with amperages of 50 or higher.

Q: Are plasma cutters accurate?

A: In short, yes, plasma cutters are known to be very accurate when used correctly. Because plasma cutters have very thin kerfs, it allows you to cut complex or detailed patterns out of metal with enough skill and practice.

Conclusion

There we have it, our list of the best plasma cutters available and their key components. We hope that you leave here with more knowledge on plasma cutters and you have a better idea which one is the best choice for you. Thank you dear reader and happy cutting!